Produce DAF waste oil qualified for the renewable energy and biofuels markets

By Kevin Bell, Owner and CEO of GTech

The Echo range of 3 phase centrifuges by GTech is a step-change for the industry. Locally made and supplied using our in-house engineering and manufacturing network, the Echo range has a short production lead time. Built for reliability and efficiency, the GTech 3 phase decanter range provides proven performance and industry-leading safety features, combined with a low cost of ownership. Offering new levels of control, speed and reliability, this series will transform the way you manage waste, recover valuable oils, and produce clean, clear water. From water, to oil, to food, a focus on reducing waste, recovering valuable materials, and maximizing everything we use introduces new value opportunities and increased efficiency to a wide range of industrial, wastewater, oil and gas, and food by-product industries.

The Echo range of 3 phase centrifuges by GTech is a step-change for the industry. Locally made and supplied using our in-house engineering and manufacturing network, the Echo range has a short production lead time. Built for reliability and efficiency, the GTech 3 phase decanter range provides proven performance and industry-leading safety features, combined with a low cost of ownership. Offering new levels of control, speed and reliability, this series will transform the way you manage waste, recover valuable oils, and produce clean, clear water. From water, to oil, to food, a focus on reducing waste, recovering valuable materials, and maximizing everything we use introduces new value opportunities and increased efficiency to a wide range of industrial, wastewater, oil and gas, and food by-product industries.

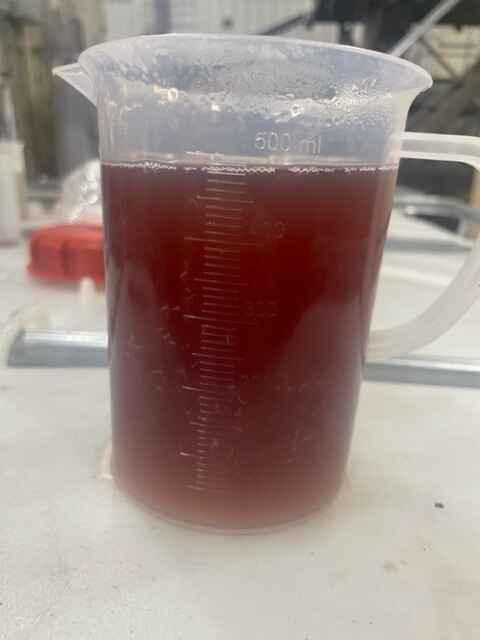

A good example of the value opportunity created by three-phase technology exists within the chicken, pork, and beef industries. The valuable price of oils and fats, the limited global supply and the increasing demand for biofuels are creating opportunities to recover DAF skim and extract sellable oil/grease at market price. Recycling DAF skim containing oil greatly improves our clients’ P and L by taking a cost/waste stream and converting it into a monetary benefit.

Using a GTech skid system with an Echo 4 decanter, one GTech pork processing client has been able to process their DAF and extract reusable oil sold into the renewable and biofuel markets. They have significantly reduced their DAF waste disposal costs,  including transportation. In addition to the top-line value stream created by extracting the fat from this waste stream, this client has found other advantages and cost reductions.

including transportation. In addition to the top-line value stream created by extracting the fat from this waste stream, this client has found other advantages and cost reductions.

Maintaining a consistent and constant operational flow of the waste stream is another benefit of three phase separation technology. This operator leverages GTech’s Echo 4’s fully variable paring pump for the light phase. This on-the-fly adjustment optimizes operations and maximizes their uptime because the centrifuge doesn’t have to be powered down to make such optimizing adjustments, which can lose valuable processing hours to come back online. Paired with GTech’s proprietary operational software and in-house designed and assembled panels, this Ohio Plant has established a benchmark for oil and grease reclamation.

For over 35 years, GTech has been building a global reputation for developing innovative, industrial-grade equipment and industry-leading technology solutions designed for the circular economy. Built in Texas, our latest high-quality, industrial-grade Three-Phase Echo separation range allows you to recover and reuse valuable resources, reduce waste, improve efficiency, and add value to the bottom line. This product range is a step change for the sector. From Texas, we also provide tailored skids that offer industry-leading mobility and efficiency and support our products with service and parts. Our experienced team of in-house designers and engineers, based across the global GTech network, also enables us to tailor solutions to our customers’ individual needs.

innovative, industrial-grade equipment and industry-leading technology solutions designed for the circular economy. Built in Texas, our latest high-quality, industrial-grade Three-Phase Echo separation range allows you to recover and reuse valuable resources, reduce waste, improve efficiency, and add value to the bottom line. This product range is a step change for the sector. From Texas, we also provide tailored skids that offer industry-leading mobility and efficiency and support our products with service and parts. Our experienced team of in-house designers and engineers, based across the global GTech network, also enables us to tailor solutions to our customers’ individual needs.

For more information contact GTech at info@gtechus.com