Case Study: 3D Solutions

NEW GTECH MACHINE TRANSFORMS OPERATION

GTech interview: Tim Lloyd, Plant Manager

After experiencing significant reliability and service issues with other major-brand separation machines, 3D Solutions turned to GTech and its industry-leading Echo-4 3 phase decanter. The result was not only an increase in reliability and support, but a massive improvement in efficiency, which has changed the way the business works.

After experiencing significant reliability and service issues with other major-brand separation machines, 3D Solutions turned to GTech and its industry-leading Echo-4 3 phase decanter. The result was not only an increase in reliability and support, but a massive improvement in efficiency, which has changed the way the business works.

Established in 2002, 3D Solutions is a leading manufacturer of high-quality protein ingredients for the pet food industry. The protein is provided in fresh, frozen and dry fats form for use in a range of premium pet food brands.

Following a series of catastrophic failures from a competitor’s separation machine they had been using, which caused 3D Solutions’ protein extraction facility to lose half its processing capacity for over six weeks, the business decided to introduce one of two recently purchased GTech Echo-4s to its protein extraction operation.

Confidence in quality

Plant Manager – Protein Solutions Tim Lloyd says they made the decision to introduce the Echo-4 to his plant after thoroughly reviewing its design and specifications.

“I could tell just by the way it had been assembled and the parts GTech had used that it was going to be a very reliable piece of equipment,” says Tim.

“Also, the adjustable dam process was a big deal because the old machines are all manual. You have to tune them in, and that’s very time consuming. They also required a lot of parts to be able to fine tune the machines, which the Echo-4 didn't.”

“The other thing I liked about the Echo-4 was the drive mechanism – and what I could see was its built-in quality.”

Step-change in efficiency

Tim says despite having confidence in the design the 3D Solutions team were still surprised by its performance when it was first introduced to their production.

“It's been awesome,” says Tim. “Even when we put it in, we didn't really know what we were going to get. And right now, we have a machine that can take up 80% of our load.”

“We also found that being able to separate out three phases of our material made the rest of our equipment a lot more efficient. So, we gained efficiencies to give us almost 25% more yield on our dry side.”

“The first day we started up there was a huge, huge improvement – enough that we had to go back and re-evaluate what we thought were our capabilities. With our facility and our equipment, we didn't realize what we had just because the other pieces of equipment were so inefficient before the difference of being able to separate the three stages.”

The machine has been so efficient, in fact, that not only can it carry a greater production load, but it also reduces the need for other processing.

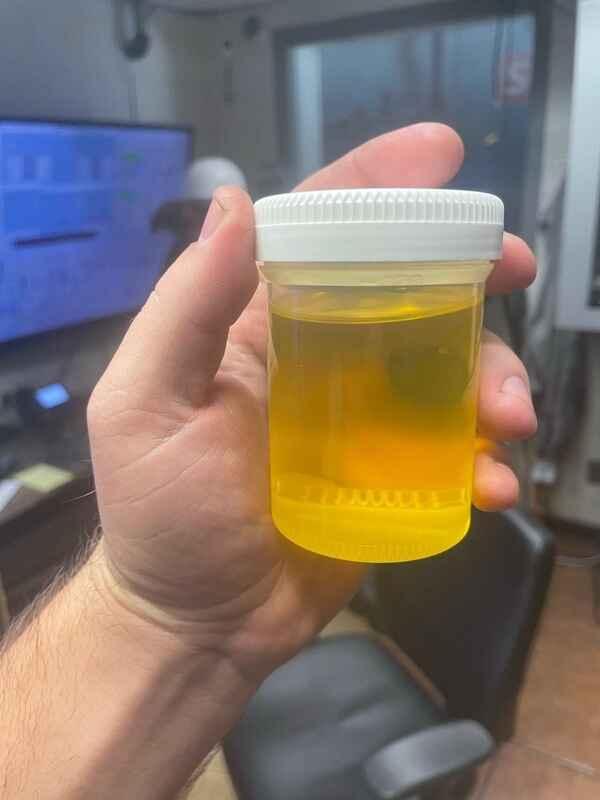

“When we first started up that machine, we checked for moisture in our fat, and the Echo-4 was able to produce a .06% moisture. We actually have a polisher that was designed to help get the moisture out of it. If you had to, you wouldn't have had to run a polisher, just because of how well this machine could separate it out. Just pure, very, very clean fat out of decanter which is something we've never had before.”

Expert service and support

The other key advantage Tim has seen is the benefit of working with GTech’s expert team.

“That's the great thing about GTech,” says Tim. “We can call them night or day, and they'll get online and call into the machine, and they'll check things out.”

“We haven't had a question where we haven’t been able to call and get a hold of Matty or Kevin. They respond very quickly, very knowledgeably. They send us right in the right direction, give us answers and help educate us on the equipment if we have any questions.”

“So, not only does the machine operate at high standards, just what Kevin and Kevin's team does is phenomenal. I don't see that very often with a lot of their industry or other companies as far as the relationship. They really take a lot of pride in their equipment.”

Stand out return on investment

In terms of the investment, Tim says there really is no comparison with other competitor 3 phase decanters.

“For the cost of the GTech machine, it is very comparable with the other ones, but I can't even put it in the same class because it runs so much more efficiently.”

“You can't compare it as far as I'm concerned, just because they’re all about the same price. But what the GTech machine produces is worth far more. I don't even think about the cost, to be quite honest with you. I'm more impressed with how it's run and the quality of material I get out of that piece of equipment.”

Reduced environmental costs

As a result, 3D Solutions is in the process of planning to introduce additional GTech machines, including a newly purchased dual disc stack that enables the business to manage its environmental footprint.

“We use steam to cook the chicken. When you do that, you have solids in that steam off the A vat – we call that stick water. So that stick water has got a lot of BOD and that affects our wastewater.”

“What we decided to do was spin that out before it gets into the A vat to avoid fouling our plates and then being able to clean the water. We then also gather some of that protein and solids and then put it back in our process to help us increase our yields even more.”

Tim says cleaning wastewater is not only a major environmental concern – particularly with local treatment plants under increasing pressure, but it can also save a business considerable cost.

“A company could end up with $100,000 a month in BOD surcharges,” says Tim. “So, in a year's time, that’s $1.2 million. If there’s any way that you can sort that out and knock those costs down, that's big money.”

“Being a company that focuses on green energy and the environment is a big deal for a lot of people. You don't want to be known as a polluter. They’re looking at what you're doing for your carbon footprint, your pollution control and your energy conservation, so it is a big deal.”

The GTech difference

While the business has been very impressed with the Echo-4, it’s what the GTech team provides that continues to make the difference for 3D Solutions.

“The mechanics love it because the machine runs flawlessly. They absolutely love it,” says Tim.

“But I would like to say it's the service that Kevin and his team provides that makes the difference,” says Tim.

“I've been in the business for 30 years and I have not met anybody like his team and how knowledgeable they are. When his team shows up, they're very helpful, very hard workers. I mean it's just phenomenal. I've enjoyed every minute working with the team.”